Pneumatic Conveying Systems

INTRODUCTION

Pneumatic conveying systems are integral to efficient material handling in various industrial operations. These systems use air pressure or vacuum to transport bulk materials through a pipeline. This guide will provide a detailed overview of how pneumatic conveying systems work, including their key components, types, and benefits.

WHAT IS PNEUMATIC CONVEYING?

Pneumatic conveying is a method of moving bulk materials through a pipeline using air or gas. This technique is widely used in industries such as food processing, pharmaceuticals, chemical manufacturing, and more due to its efficiency and reliability.

KEY COMPONENTS OF PNEUMATIC CONVEYING SYSTEM

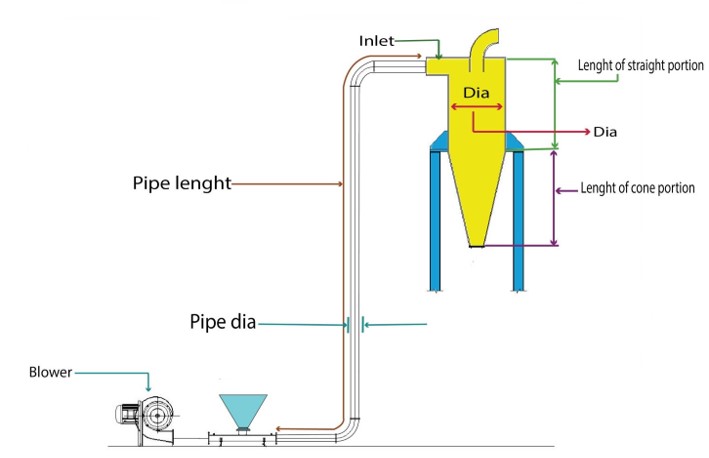

- Air Movers: These include blowers, compressors, or vacuum pumps that generate the air pressure needed to move materials.

- Pipeline: The conduit through which materials are transported. It can be made of various materials depending on the application.

- Feeding Devices: Mechanisms like rotary airlock valves or screw feeders that introduce materials into the conveying line.

- Separation Devices: Cyclones or filters that separate the conveyed materials from the air stream at the destination.

- Control Systems: Automated systems that monitor and control the pressure, flow rate, and other parameters to ensure efficient operation.

How Pneumatic Conveying Systems Work

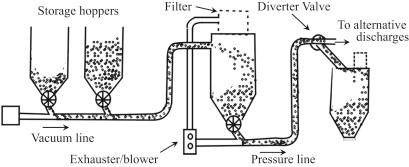

Pneumatic conveying systems operate based on two main principles: positive pressure systems and vacuum systems.

- Positive Pressure Systems: These systems use a blower or compressor to push materials through the pipeline. They are suitable for conveying materials over long distances and at higher capacities.

- Vacuum Systems: These systems use a vacuum pump to create a suction that pulls materials through the pipeline. They are ideal for shorter distances and when a cleaner environment is required.

Types of Pneumatic Conveying Systems

- Dilute Phase Conveying: Materials are suspended in the conveying air stream and transported at high velocity. This method is suitable for light and non-abrasive materials.

- Dense Phase Conveying: Materials are moved in a slug or plug form at a lower velocity. This method is ideal for heavier, abrasive, or fragile materials.

Benefits of Pneumatic Conveying Systems

- Efficiency: Pneumatic systems can move materials quickly and efficiently over long distances.

- Versatility: They can handle a wide range of materials, from fine powders to large granules.

- Cleanliness: Enclosed pipelines minimize dust and contamination, ensuring a cleaner environment.

- Flexibility: Systems can be easily modified or expanded to meet changing operational needs.

- Reduced Maintenance: With fewer moving parts, pneumatic systems typically require less maintenance compared to mechanical conveyors.