Powder Handling & Bulk Material Systems in Malaysia | Complete Guide 2025

Efficient powder handling is the backbone of modern manufacturing. Whether you’re processing food ingredients, pharmaceutical compounds, or industrial chemicals, the right bulk material handling system can transform your production efficiency, product quality, and workplace safety. At Drymat Process Engineering, we specialize in delivering complete powder handling solutions that Malaysian industries trust.

What is Powder Handling and Why Does It Matter?

Powder handling refers to the complete process of receiving, transporting, storing, processing, and packaging powdered and granular materials. Effective powder handling systems minimize product loss, reduce contamination risks, eliminate dust emissions, and optimize production throughput.

For Malaysian manufacturers, proper bulk material management isn’t just about moving materials—it’s about protecting your investment, ensuring product consistency, meeting regulatory requirements, and creating safe working environments for your team.

Complete Powder Handling Systems: An Integrated Approach

Complete Powder Handling Systems: An Integrated Approach

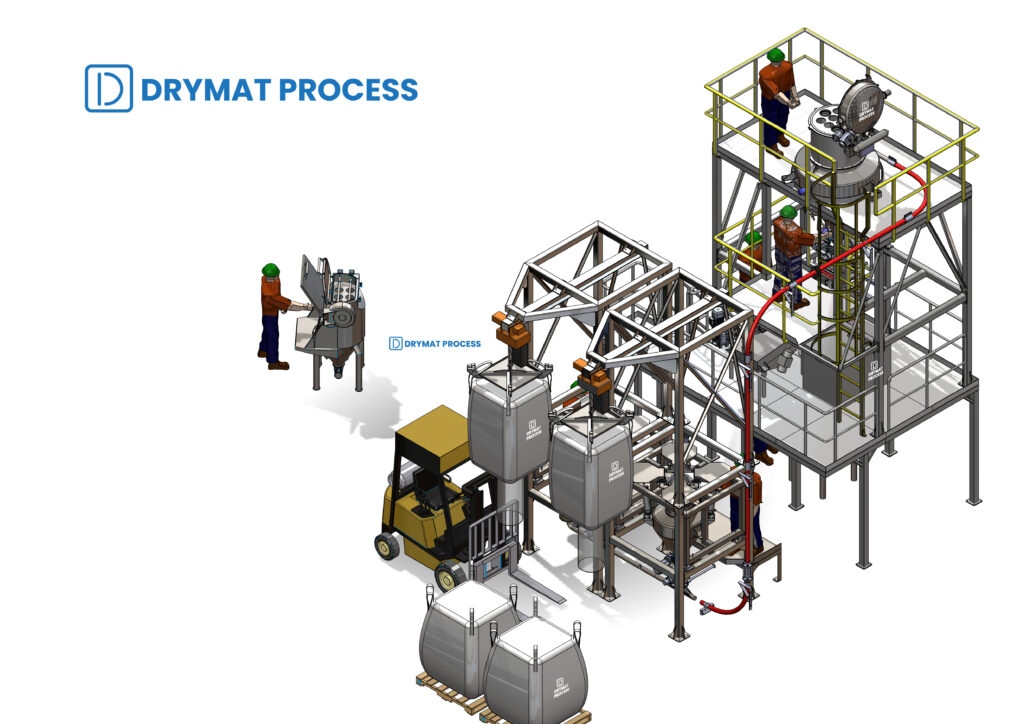

At Drymat Process, we don’t just supply isolated equipment. We design integrated powder handling and bulk material systems where every component works together seamlessly. Our complete solutions typically include:

- Material reception through tipping stations

- Transport systems using pneumatic conveying or screw conveyors

- Processing equipment including powder mixers and vibrating sieves

- Flow control via rotary valves and diverter valves

- Environmental protection through dust collector systems

This integrated approach ensures your powder handling operation runs efficiently from raw material arrival through final product packaging.

Pneumatic Conveying Systems: Clean, Efficient Material Transport

Pneumatic conveying represents one of the most versatile technologies for powder handling in modern facilities. This method uses air pressure or vacuum to move bulk material through enclosed pipelines, offering significant advantages over traditional mechanical conveyors.

How Pneumatic Conveying Works

A pneumatic conveying system transports powders and granules by suspending or pushing them through pipes using compressed air or vacuum. This enclosed transport method eliminates dust emissions, prevents contamination, and provides flexible routing that adapts to complex plant layouts.

Lean Phase Pneumatic Conveying

Lean phase pneumatic conveying moves materials at high velocities, fully suspending particles in the air stream. This pneumatic conveying method excels when you need:

- Fast material transport across long distances

- High throughput rates for bulk material handling

- Cost-effective installation with smaller pipe diameters

- Multiple pick-up or delivery points throughout your facility

Lean phase systems are ideal for robust materials like plastic pellets, flour, sugar, and cement where particle breakage isn’t a concern.

Dense Phase Pneumatic Conveying

For fragile or abrasive materials, dense phase pneumatic conveying provides gentle, low-velocity transport. This specialized bulk material handling method moves powders in concentrated plugs, offering:

- Minimal product degradation protecting material quality

- Reduced equipment wear from abrasive substances

- Lower energy consumption improving operational costs

- Quieter operation for better workplace environments

Dense phase pneumatic conveying is perfect for pharmaceutical powders, specialty chemicals, cocoa powder, and other high-value materials where maintaining particle integrity is critical.

Applications Across Malaysian Industries

Our pneumatic conveying systems serve diverse sectors including food manufacturing, pharmaceutical production, chemical processing, plastics manufacturing, and construction materials. Each pneumatic conveying installation is customized for your specific powder handling requirements.

Screw Conveyor Systems: Reliable Mechanical Material Transport

When pneumatic conveying isn’t the optimal solution, our screw conveyor systems provide dependable mechanical transport for powder handling applications. A screw conveyor uses a rotating helical screw blade inside a tube or trough to move bulk material from one point to another.

Types of Screw Conveyor Configurations

Horizontal Screw Conveyor: Ideal for level bulk material transport across short to medium distances. Horizontal screw conveyor systems are perfect for feeding powder mixers, connecting process equipment, and distributing materials to multiple destinations.

Inclined Screw Conveyor: When you need to elevate bulk material, inclined screw conveyor systems provide efficient vertical transport. These are commonly used to feed materials from a tipping station into elevated storage vessels.

Vertical Screw Conveyor: For maximum space efficiency, vertical screw conveyor designs lift powder handling materials straight up, ideal for tight plant layouts or when connecting ground-level equipment to mezzanine-level processes.

Screw Conveyor Design Features

Our screw conveyor systems feature:

- Dust-tight construction preventing powder handling emissions

- Easy maintenance access reducing downtime

- Various material options (carbon steel, stainless steel, special alloys)

- Optional jacketed troughs for temperature-sensitive bulk material

- Variable speed drives for precise flow control

The screw conveyor technology we provide handles everything from free-flowing powders to sticky or cohesive substances, with shafted, shaftless, ribbon flight, and paddle configurations tailored to your specific needs.

Dust Collector Systems: Essential Environmental Protection

No powder handling or bulk material system is complete without effective dust control. Our dust collector systems capture airborne particles at every potential emission point, protecting worker health, ensuring regulatory compliance, and preventing valuable product loss.

Why Dust Collection Matters

Airborne dust from powder handling operations poses serious risks:

- Health hazards: Respiratory issues for workers exposed to dust

- Safety risks: Combustible dust can cause explosions

- Product loss: Escaped powder represents wasted material

- Compliance issues: Violations of environmental regulations

- Equipment damage: Dust accumulation causes premature wear

A properly designed dust collector eliminates these risks while improving overall bulk material handling efficiency.

Cartridge Dust Collector Technology

Cartridge-style dust collector units provide superior filtration in compact footprints. These dust collector systems excel for fine powder handling applications where sub-micron particle capture is essential. Features include:

- High-efficiency filtration capturing 99.9% of particles

- Compact design requiring minimal floor space

- Easy cartridge replacement reducing maintenance time

- Pulse-jet cleaning extending filter life

- Optional explosion protection for combustible dust

Our cartridge dust collector installations integrate seamlessly with tipping stations, vibrating sieves, and pneumatic conveying systems.

Bag Filter Dust Collector Solutions

For high-volume air handling, bag filter dust collector systems deliver proven performance. These dust collector configurations manage larger air volumes generated by multiple powder handling operations, providing centralized dust collection for entire production areas.

Whether you need standalone dust collector units for specific equipment or centralized systems managing multiple bulk material handling points, Drymat Process engineers solutions matching your exact requirements.

Vibrating Sieve Equipment: Quality Control Through Screening

Product quality depends on consistent particle size. Our vibrating sieve systems provide precise screening that removes oversize particles, agglomerates, and foreign materials from your powder handling stream, ensuring only specification-grade bulk material reaches your customers.

How Vibrating Sieve Technology Works

A vibrating sieve uses rapid vibration to separate particles by size. Material feeds onto the screen surface, and vibration causes smaller particles to pass through mesh openings while retaining larger particles. This screening process is essential for powder handling quality control.

Multi-Deck Vibrating Sieve Systems

Single-pass, multi-fraction separation is possible with multi-deck vibrating sieve units. These vibrating sieve systems simultaneously separate bulk material into multiple size ranges, improving process efficiency. Applications include:

- Removing agglomerates after powder mixer operations

- Classifying materials into multiple product grades

- Scalping oversize contamination from incoming bulk material

- Final screening before packaging ensuring consistency

- Integration with pneumatic conveying for continuous processing

Sanitary Vibrating Sieve Designs

Food and pharmaceutical powder handling demands hygienic equipment. Our sanitary vibrating sieve systems feature polished stainless steel construction, tool-free disassembly, and designs meeting USDA and FDA requirements. These vibrating sieve units integrate with dust collector systems for contained, clean processing.

The vibrating sieve technology we supply ranges from compact safety screeners to high-capacity production units processing multiple tons per hour of bulk material.

Rotary Valve Systems: Precision Flow Control

Material flow control is critical in powder handling operations. Our rotary valve equipment provides reliable feeding and airlock functions that maintain system efficiency. Each rotary valve serves as both a precision metering device and pressure seal—essential components in pneumatic conveying systems and bulk material processing lines.

Drop-Through Rotary Valve Configuration

Drop-through rotary valve designs excel in gravity feeding applications. These rotary valve units precisely meter bulk material from storage hoppers into screw conveyor systems, powder mixer equipment, or packaging machinery. Features include:

- Precise volumetric feeding for process control

- Minimal material degradation protecting product quality

- Simple, reliable operation with low maintenance

- Various rotor designs for different powder handling materials

- Optional variable speed control for flow adjustment

Blow-Through Rotary Valve for Pressure Systems

In pressurized pneumatic conveying systems, blow-through rotary valve configurations provide essential airlock functions. These specialized rotary valve units withstand pressure differentials while maintaining consistent material feed rates. Our blow-through rotary valve designs feature:

- Heavy-duty construction for pressure applications

- Minimal air leakage maintaining system efficiency

- Wear-resistant materials for abrasive bulk material

- Explosion-proof options for combustible dust handling

- Integration with upstream or downstream equipment

Whether feeding a pneumatic conveying system, controlling flow from a diverter valve, or metering bulk material into a powder mixer, proper rotary valve selection significantly impacts overall powder handling performance.

Tipping Station Equipment: Safe Material Reception

Efficient powder handling begins at material reception. Our tipping station systems provide ergonomic, dust-controlled unloading of bagged materials, transforming manual dumping into efficient, safe processes that protect workers and product quality.

Bag Dump Tipping Station Benefits

Manual bag dumping creates dust exposure and physical strain. Our bag dump tipping station equipment eliminates these issues through:

- Ergonomic bag support reducing worker injury risk

- Integrated dust collector connections capturing emissions at source

- Optional bag cutting tools expediting the dumping process

- Containment systems preventing product contamination

- Discharge connections to screw conveyor or pneumatic conveying systems

The tipping station serves as the critical interface between packaged material receipt and your automated powder handling system, establishing controlled, clean material entry.

Bulk Bag Tipping Station Solutions

For operations receiving bulk material in FIBCs (flexible intermediate bulk containers), our bulk bag tipping station systems provide complete unloading solutions. These tipping station installations feature:

- Robust frame structures supporting up to 2,000 kg

- Bag activation systems for controlled discharge

- Dust collector integration for emission-free operation

- Discharge connections to downstream equipment

- Optional bag compaction systems for waste management

A properly designed tipping station transforms material reception from a dust-generating bottleneck into an efficient, controlled process feeding materials consistently into your powder handling system.

Powder Mixer Systems: Achieving Blend Uniformity

Product consistency depends on thorough mixing. Our powder mixer systems deliver homogeneous blends regardless of ingredient density differences, particle size variations, or batch size requirements. Each powder mixer is engineered for your specific formulation challenges.

Ribbon Blender Powder Mixer

The ribbon blender powder mixer is the industry standard for gentle, thorough powder handling applications. This powder mixer design features counter-rotating ribbon agitators moving bulk material in opposing directions, achieving complete homogeneity typically within 10-15 minutes.

Ribbon blender powder mixer applications include:

- Food ingredient blending for nutritional uniformity

- Chemical powder formulations requiring precise ratios

- Pharmaceutical powder mixing meeting regulatory standards

- Dry mortar and construction material blending

- Pet food and animal feed manufacturing

Our ribbon blender powder mixer systems include optional liquid addition, specialized coatings for abrasive bulk material, sanitary designs for food and pharmaceutical applications, and discharge connections to vibrating sieve or packaging equipment.

Paddle and High-Intensity Powder Mixer Options

Difficult-to-blend formulations require aggressive mixing. Our high-intensity powder mixer systems deliver the energy necessary to disperse minor ingredients and break up agglomerates. These powder mixer designs are ideal when pneumatic conveying delivers ingredients from multiple sources.

Tumble and V-Blender Powder Mixer Technology

For fragile materials requiring gentle handling, tumble-style powder mixer equipment provides low-shear blending. These powder mixer systems are perfect for bulk material that degrades under aggressive agitation.

Whether blending large production batches or small R&D quantities, the powder mixer technology we provide ensures consistent product quality batch after batch.

Diverter Valve Systems: Flexible Material Routing

Manufacturing flexibility demands adaptable bulk material handling. Our diverter valve systems provide precise flow control in powder handling operations with multiple destinations, enabling efficient product changeovers and multi-product processing.

Two-Way Diverter Valve Applications

Simple routing applications use two-way diverter valve designs directing material flow to alternate destinations. These diverter valve units are commonly installed in:

- Pneumatic conveying systems routing to different storage silos

- Screw conveyor discharge points feeding multiple powder mixers

- Vibrating sieve discharge directing on-spec and off-spec bulk material

- Material transfer points requiring alternating destinations

Three-Way Diverter Valve for Complex Operations

Operations requiring distribution to three destinations employ three-way diverter valve configurations. These diverter valve systems provide maximum routing flexibility, enabling:

- Single pneumatic conveying systems serving multiple process lines

- Bulk material distribution from centralized storage to numerous locations

- Flexible powder handling in multi-product facilities

- Emergency routing to alternate destinations during maintenance

Diverter Valve Design Options

The diverter valve technology we supply includes:

- Flap-style diverter valve for clean, positive shutoff

- Slide-gate diverter valve for abrasive bulk material

- Pneumatically actuated diverter valve for automatic control

- Electrically actuated diverter valve for PLC integration

- Manual diverter valve for simple applications

Each diverter valve features quick-change wear components, dust-tight construction, and position feedback for process control. Properly applied diverter valve equipment transforms rigid powder handling systems into flexible production assets.

Integrated System Design: Complete Solutions

While individual components are important, true operational excellence comes from integrated system design. Drymat Process Engineering excels at creating complete powder handling and bulk material systems where every component works seamlessly together.

Our System Integration Approach

Material Reception: Your powder handling system begins at the tipping station, where materials enter your facility safely and dust-free.

Primary Transport: Depending on distance, material characteristics, and layout, we specify either pneumatic conveying or screw conveyor systems for primary bulk material transport.

Processing: Materials flow through vibrating sieve equipment for quality control and powder mixer systems for blending operations.

Flow Control: Strategically positioned rotary valve and diverter valve equipment maintains consistent material flow and routing flexibility.

Environmental Protection: Comprehensive dust collector systems integrate at every potential emission point throughout your powder handling operation.

This integrated approach considers material characteristics, throughput requirements, plant layout, safety standards, and maintenance accessibility to deliver optimized bulk material handling performance.

Industries We Serve Across Malaysia

Drymat Process Engineering provides powder handling, bulk material, and pneumatic conveying solutions across diverse Malaysian industries:

Food Manufacturing

From ingredient reception at the tipping station through pneumatic conveying to storage, powder mixer blending, and final vibrating sieve screening before packaging, we design hygienic powder handling systems meeting strict food safety standards. Our food-grade screw conveyor, sanitary rotary valve, and FDA-compliant dust collector equipment ensures product safety.

Pharmaceutical Production

Pharmaceutical powder handling demands the highest contamination control. Our contained tipping station designs, sanitary pneumatic conveying systems, validation-ready powder mixer equipment, and cleanroom-compatible dust collector installations support API handling and drug product manufacturing.

Chemical Processing

Chemical bulk material handling requires specialized equipment. Our corrosion-resistant pneumatic conveying systems, chemical-compatible screw conveyor designs, abrasion-resistant rotary valve units, and explosion-protected dust collector installations serve chemical manufacturers safely.

Plastics and Polymers

Resin powder handling utilizes our pneumatic conveying technology, diverter valve routing flexibility, powder mixer equipment for masterbatch production, and vibrating sieve systems for regrind screening.

Construction Materials

Cement, fly ash, and dry mortar facilities rely on our heavy-duty bulk material handling equipment including robust screw conveyor systems, high-capacity pneumatic conveying installations, industrial-grade rotary valve components, and powerful dust collector solutions.

Why Choose Drymat Process Engineering?

Complete System Integration

We design complete powder handling and bulk material systems where tipping station, pneumatic conveying, screw conveyor, dust collector, vibrating sieve, rotary valve, powder mixer, and diverter valve components are engineered to work perfectly together.

Local Expertise and Support

Based in Malaysia, we understand local industry requirements, building codes, and operational challenges. Our engineering team provides responsive service, readily available spare parts for rotary valve, diverter valve, and other critical components, plus technical support when you need it.

Proven Technology

We supply only proven pneumatic conveying, screw conveyor, powder mixer, vibrating sieve, and bulk material handling equipment from reputable manufacturers, ensuring long-term reliability.

Custom Engineering

Every powder handling challenge is unique. Whether you need a simple screw conveyor connecting two processes or a complex pneumatic conveying system with multiple diverter valve routing options and integrated dust collector protection, we engineer solutions specifically for your requirements.

Safety Focus

Worker safety drives our design philosophy. From ergonomic tipping station equipment reducing injury risk, to comprehensive dust collector systems protecting respiratory health, to explosion-protected components for combustible dust handling, safety is built into every powder handling system we deliver.

Quality Assurance

Our bulk material systems deliver reliable, long-term performance. We specify appropriate vibrating sieve construction, size rotary valve components correctly, design pneumatic conveying systems with adequate capacity, and engineer powder mixer equipment for consistent blends.

Getting Started: Your Powder Handling Project

Transforming your powder handling and bulk material operations begins with understanding your specific requirements. The Drymat Process Engineering team will evaluate your current processes, identify opportunities, and recommend optimal solutions.

Our Project Process

Initial Consultation: We discuss your materials, throughput requirements, space constraints, and goals. This helps us understand whether pneumatic conveying or screw conveyor technology suits your needs, what dust collector capacity you require, and how tipping station, vibrating sieve, powder mixer, and diverter valve equipment should integrate.

Site Assessment: Our engineers visit your facility to evaluate existing equipment, measure available space, assess structural capabilities, and understand material flow requirements for optimal powder handling system design.

System Design: We develop detailed designs showing pneumatic conveying routing, screw conveyor placement, dust collector locations, vibrating sieve positions, rotary valve and diverter valve installations, plus all supporting bulk material handling equipment.

Equipment Supply: Once approved, we procure all system components including pneumatic conveying equipment, screw conveyor units, dust collector systems, vibrating sieve machines, rotary valve and diverter valve assemblies, tipping station installations, and powder mixer equipment.

Installation Support: Our team provides installation supervision ensuring powder handling systems are built correctly. We verify pneumatic conveying pipeline integrity, confirm screw conveyor alignment, validate dust collector connections, and ensure all rotary valve and diverter valve components are installed properly.

Commissioning and Training: Before handover, we commission complete systems, testing pneumatic conveying performance, screw conveyor throughput, dust collector efficiency, vibrating sieve screening, rotary valve feed rates, and powder mixer blend uniformity. Your operators receive comprehensive training on all bulk material handling equipment.

Ongoing Support: We provide ongoing technical support, spare parts for rotary valve, diverter valve, and other wear components, preventive maintenance guidance, and system optimization assistance.

Frequently Asked Questions About Powder Handling

Q: What’s better for my application—pneumatic conveying or screw conveyor?

A: Pneumatic conveying excels for longer distances, multiple destinations, and applications requiring enclosed transport. A screw conveyor is typically more economical for shorter distances and higher bulk densities. We’ll recommend the optimal powder handling technology based on your specific requirements.

Q: How do I know what size dust collector I need?

A: Dust collector sizing depends on the air volume generated by your powder handling equipment, dust concentration, particle characteristics, and required filtration efficiency. Our engineers calculate exact dust collector specifications for your application.

Q: Can one powder mixer handle multiple product formulations?

A: Yes, modern powder mixer designs feature quick-cleaning capabilities and changeover procedures that allow efficient multi-product operation. We’ll specify a powder mixer with appropriate features for your product range.

Q: How does a rotary valve maintain airlock in pneumatic conveying?

A: The rotary valve creates multiple sequential seals between its rotor pockets and housing, preventing air from escaping while still allowing bulk material to flow. Proper rotary valve selection ensures efficient pneumatic conveying system operation.

Q: What maintenance does a vibrating sieve require?

A: Regular vibrating sieve maintenance includes screen inspection and replacement, checking vibration motor bearings, and verifying mounting isolators. We provide detailed maintenance schedules for all powder handling equipment.

Q: How does a diverter valve improve system flexibility?

A: A diverter valve allows one pneumatic conveying or screw conveyor system to serve multiple destinations, reducing equipment investment while providing routing flexibility for different bulk material products or process lines.

Take the Next Step in Powder Handling Excellence

Efficient powder handling and bulk material management are essential for manufacturing competitiveness. Whether you need to replace aging equipment, expand production capacity, improve product quality, enhance workplace safety, or reduce operational costs, Drymat Process Engineering has the expertise and technology to help.

Our comprehensive solutions encompass every aspect of powder handling—from material reception at the tipping station, through transport via pneumatic conveying or screw conveyor, processing with powder mixer and vibrating sieve equipment, flow control using rotary valve and diverter valve systems, to environmental protection via dust collector installations.

Contact Drymat Process Engineering today to discuss your powder handling and bulk material requirements. Our engineering team is ready to evaluate your application and recommend optimal solutions that will transform your operations.

Let Drymat Process Engineering become your trusted partner for cleaner, safer, more efficient powder handling throughout Malaysia.

Drymat Process Engineering

Complete Powder Handling & Bulk Material Systems

Pneumatic Conveying | Screw Conveyor | Dust Collector | Vibrating Sieve

Rotary Valve | Tipping Station | Powder Mixer | Diverter Valve

Serving Malaysia’s Food, Pharmaceutical, Chemical, Plastics, and Construction Industries

Our LinkedIn : Drymat Process Sdn Bhd