Powder Handling & Bulk Material Systems in Malaysia

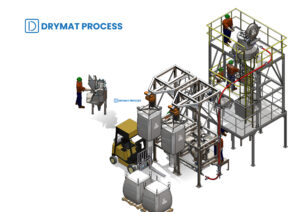

At Drymat Process, we specialize in designing and supplying complete powder handling systems and bulk material equipment for industries in Malaysia. Our solutions ensure safe, efficient, and reliable handling of powders, granules, and bulk solids — helping your operations achieve consistent quality and productivity.

Whether you need a pneumatic conveying system, dust collector, or screw conveyor, Drymat Process provides engineering expertise and equipment trusted by leading manufacturers.

Powder Handling System

Our powder handling systems are built to move, store, and process powders with maximum efficiency. From raw material unloading to mixing and packaging, we deliver end-to-end solutions tailored to your plant requirements.

Bulk Material System

Handling bulk solids requires precision and reliability. Drymat Process designs bulk material systems that cover conveying, dosing, mixing, and storage — ensuring smooth material flow across your production line.

Pneumatic Conveying System

We provide customized pneumatic conveying systems for transporting powders and granules using air pressure. Depending on your needs, we offer both:

-

Lean Phase Conveying – fast and cost-effective.

-

Dense Phase Conveying – gentle on fragile materials.

Applications include food, chemical, and pharmaceutical industries across Malaysia.

Screw Conveyor

Our screw conveyors are designed for reliable material transport within your process line. They are ideal for powders, grains, and bulk solids, with options for horizontal, inclined, or vertical conveying.

Dust Collector

A clean environment is essential for safety and compliance. Drymat Process offers advanced dust collector systems that remove airborne particles, improving air quality and protecting both equipment and workers.

Vibrating Sieve

For particle separation and size control, our vibrating sieves provide accurate screening of powders and granules. This ensures only the right-sized material continues into your production process.

Rotary Valve

We supply rotary valves for precise feeding and airlock applications. These are critical for maintaining consistent material flow between conveying and processing systems.

Tipping Station

Our tipping stations allow safe and dust-free unloading of bags or bulk materials into your process line, reducing contamination risks and improving worker safety.

Powder Mixer

Consistent mixing is key to quality. Drymat Process provides powder mixers that deliver homogeneous blends, suitable for food, chemical, and industrial powders.

Diverter Valve

For plants with multiple conveying lines, our diverter valves offer flexible material flow control — directing powders to different silos, mixers, or packaging stations.