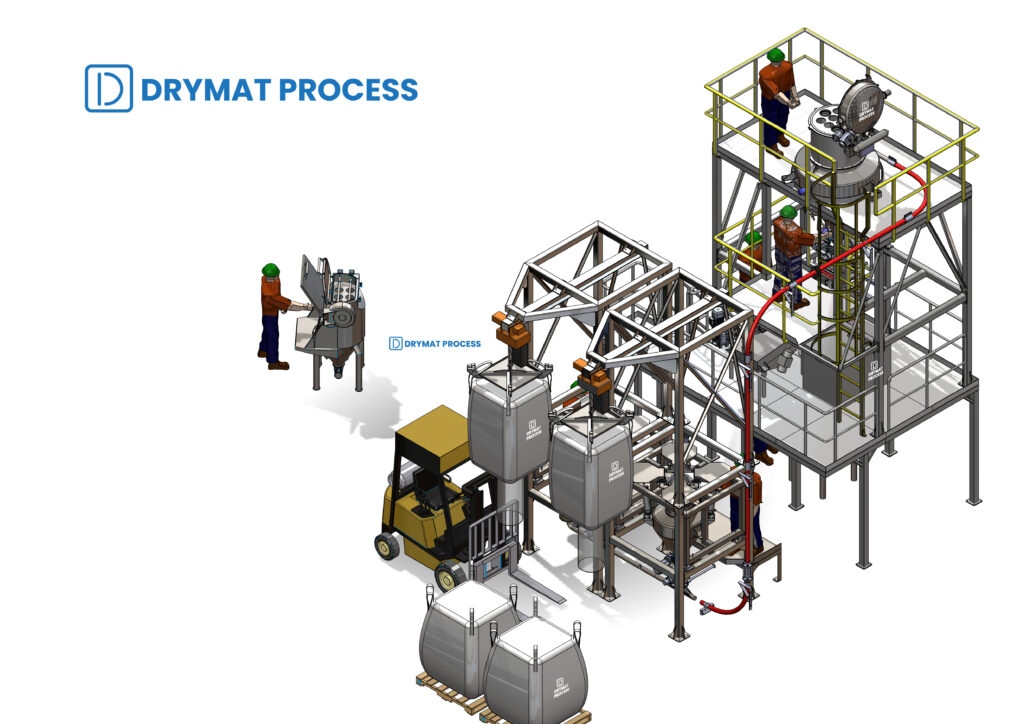

Pneumatic Conveying System in Malaysia – Manufacturer for the Food Industry

Drymat Process Sdn Bhd is a leading manufacturer of pneumatic conveying systems in Malaysia, specialising in the food industry — from flour, sugar, cocoa, and coffee to various powdered ingredients. With years of expertise in bulk material handling, we help food processing plants improve efficiency, reduce wastage, and maintain product hygiene according to HACCP & GMP standards.

Your Powder Solution Partner – we provide complete solutions from design, fabrication, installation, and commissioning to after-sales maintenance.

Pneumatic Conveying System Malaysia

What is a Pneumatic Conveying System? Click Here

A pneumatic conveying system is a method of transferring bulk powder materials through an air stream within enclosed pipelines. It is widely used in the food industry because it:

-

Ensures hygiene and contamination-free transfer.

-

Minimises product loss and spillage.

-

Transfers materials over long distances without compromising quality.

Advantages of Pneumatic Conveying for the Food Industry

-

Hygiene & Safety – complies with HACCP, GMP, and international food standards.

-

Flexibility – handles various powder types efficiently.

-

Full Automation – reduces labour costs.

-

Low Maintenance – durable design and easy cleaning process.

Types of Pneumatic Conveying Systems We Offer

-

Dilute Phase Conveying – ideal for light powders and high-speed transfer.

-

Dense Phase Conveying – for fragile or heavy materials with minimal damage.

-

Vacuum Conveying – perfect for applications requiring high cleanliness and controlled environments.

Industries We Serve, We design, Pneumatic Conveying System Malaysia manufacture, and install systems for:

-

Bakery & biscuit manufacturing

-

Sugar & cocoa processing

-

Instant beverage powder production

-

Flour & grain processing

Our Expertise & Projects in Malaysia

As a manufacturer, we create custom-made systems based on capacity and plant requirements. Some of our projects include:

-

Transferring flour to mixing tanks without dust emission.

-

Delivering sugar to packaging lines.

-

Handling cocoa and coffee using dense phase systems.

Request a Quotation Today

Looking to improve your plant’s powder transfer efficiency?

📧 Email: sales@drymat-process.com

Drymat Process Sdn Bhd – Your Powder Solution Partner.